Top-Rated CO2 Fire System Inspections & Maintenance Services

Table of Contents

ToggleTop-Rated CO2 Fire System Inspections & Maintenance Services:

Safety First (Pvt.) Ltd. – Premier Inspections & Maintenance of CO2 Fire Extinguishing Systems in Chittagong, Mongla, Payra-Bangladesh.

Since 2005, Safety First (Pvt.) Ltd., an ISO 9001:2015 certified company, has been a trusted provider of fixed carbon dioxide (CO2) fire extinguishing system inspections and maintenance in Chittagong, Bangladesh. Our services are approved by various IACS classes including DNV, NKK Class, BV, LR, KR, CCS, RINA, and IRS, and strictly adhere to MSC.1/Circ.1318/Rev.1, dated 25 May 2021.

Why Choose Us?

Top-Rated CO2 Fire System Inspections

- Certified Excellence: Our ISO 9001:2015 certification ensures the highest quality standards in every service we provide.

- Expert Team: With over 15 years of experience, our certified technicians are adept at maintaining and inspecting CO2 fire extinguishing systems.

- International Approvals: We are approved by leading IACS classes such as DNV, NKK Class, BV, LR, KR, CCS, RINA, and IRS.

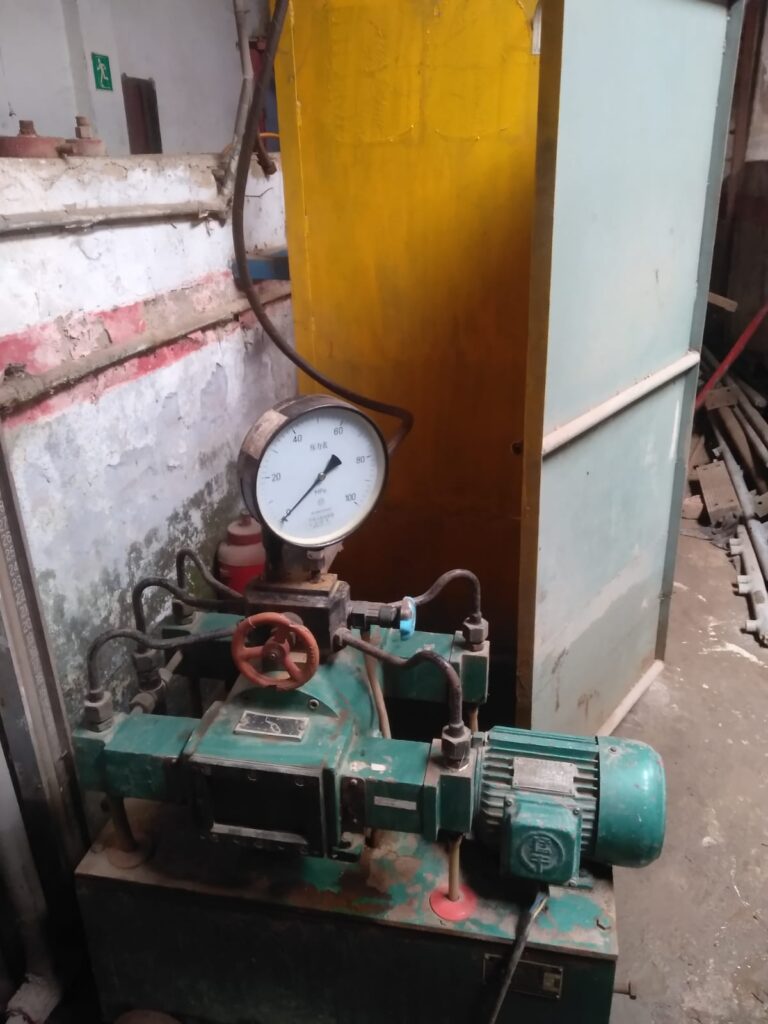

- Advanced Technology: We utilize state-of-the-art equipment for comprehensive inspections and maintenance.

- Customer-Centric Solutions: We provide tailored maintenance plans to meet your specific needs and ensure the optimal performance of your fire extinguishing systems.

Our Services Include:

Top-Rated CO2 Fire System Inspections :

CO2 Cylinder Bi-Annual Inspection & Level Check:

- Inspection: Comprehensive inspection of CO2 cylinders every two years to ensure they are in optimal condition.

- Level Check: Accurate level check using a Liquid Level Indicator Kit to verify the CO2 content within the cylinders.

CO2 Line Blow-Through

- Engine Room: Thorough blow-through of CO2 lines in the engine room to ensure no blockages and optimal flow.

- Cargo Hold: Effective CO2 line blow-through in the cargo hold to maintain system integrity and efficiency.

Testing Fan Shutdown & Activation

- Fan Shutdown: Testing the system’s ability to shut down fans in the event of a fire, preventing the spread of flames.

- Fan Activation: Ensuring fans can be turned back on safely once the fire threat is mitigated.

CO2 Pilot Cylinder Operations

- Operating Pilot Cylinder: Checking the operation of CO2 pilot cylinders to ensure they function correctly during an emergency.

- Opening CO2 Pilot Box: Inspecting and testing the CO2 pilot box to ensure it operates smoothly and reliably.

Remote Valve Operation

- Testing: Ensuring remote valves can be operated effectively from a distance, crucial for safety during emergencies.

Manifold Checking

- Inspection: Detailed inspection of manifolds to ensure there are no leaks and that all connections are secure.

- Maintenance: Routine maintenance to keep manifolds in top working condition, ensuring the efficiency of the fire extinguishing system.

By providing these comprehensive services, Safety First (Pvt.) Ltd. ensures that your CO2 fire extinguishing systems are maintained to the highest standards, guaranteeing safety and compliance.

Top-Rated CO2 Fire System Inspections

FAQs

- What is a fixed CO2 fire extinguishing system? A fixed CO2 fire extinguishing system is a fire suppression system that uses carbon dioxide gas to extinguish fires, ideal for environments where water-based suppression is unsuitable.

- Why is regular inspection and maintenance important for CO2 fire extinguishing systems? Regular inspections and maintenance are vital to ensure the system’s operational readiness in case of a fire, safeguarding both property and personnel.

- How often should CO2 fire extinguishing systems be inspected? As per MSC.1/Circ.1318/Rev.1, annual inspections by certified professionals are recommended to ensure system compliance and functionality.

- What standards do you follow for inspections and maintenance? We adhere to MSC.1/Circ.1318/Rev.1 guidelines issued on 25 May 2021, and our services are approved by leading IACS classes, ensuring top-tier quality and compliance.

- Can you customize maintenance plans for our specific needs? Yes, we offer bespoke maintenance plans tailored to your specific requirements, ensuring your CO2 fire extinguishing systems perform optimally.

CO2 Cylinders Hydro test Interval as per IMO Regulations MSC.1/Circ.1318/Rev.1

Top-Rated CO2 Fire System Inspections-Services:

According to IMO Regulations MSC.1/Circ.1318/Rev.1, the following rules and intervals apply for the hydrostatic testing (hydrotest) of CO2 cylinders used in fixed fire extinguishing systems:

- Initial Hydrotest:

- All CO2 cylinders should undergo an initial hydrostatic test before being placed into service.

- Periodic Hydrotest Interval:

- CO2 cylinders must be hydrostatically tested at intervals not exceeding 10 years. This ensures the integrity and safety of the cylinders over their service life.

- Additional Testing Requirements:

- If a CO2 cylinder shows signs of damage or corrosion, it must be hydrostatically tested immediately, regardless of the regular testing interval.

- Cylinders that have been discharged and subsequently refilled should be inspected and tested as necessary to confirm their continued fitness for service.

- Record Keeping:

- Detailed records of all hydrostatic tests, including dates, results, and any corrective actions taken, should be maintained for the life of the CO2 cylinders. These records must be available for inspection by relevant authorities.

- Inspection and Maintenance:

- In addition to hydrostatic testing, CO2 cylinders should be visually inspected annually for signs of corrosion, damage, or other issues that could affect their performance.

- Regular maintenance should be performed to ensure the valves, pressure gauges, and other components are in good working condition.

Key Points to Remember

Top-Rated CO2 Fire System Inspections-Services:

- 10-Year Interval: Hydrostatic testing every 10 years is mandatory.

- Immediate Testing: Required if damage or corrosion is detected.

- Post-Discharge Inspection: Cylinders refilled after discharge must be inspected.

- Detailed Records: Maintain thorough records of all tests and inspections.

By adhering to these regulations, you can ensure the safety and reliability of your CO2 fire extinguishing systems, in compliance with international standards.

Contact Us

Top-Rated CO2 Fire System Inspections:

For professional inspections and maintenance of your fixed CO2 fire extinguishing systems, trust Safety First (Pvt.) Ltd. Contact us today to schedule a service or to learn more about our comprehensive offerings.

Safety First (Pvt.) Ltd. – Ensuring Safety and Excellence Since 2005.